Choosing a Scaffolding Supplier with Scaffold Manufacturing Expertise

Gaining access to a project at hand to complete works contracted or required, the majority of the time is a lot easier said than done.

The reason being, if every building was as simple as a four-sided box – then designing scaffolding access for that building would take less time than it took to read this far!

The reality is a lot more complicated, many buildings be that, traditional or modern each have their own shapes, complexities and access requirements – depending on the task at hand.

The Scaffolding Supplier Process

When a customer contacts a scaffolding supplier, or scaffold hire and sales company. The scaffolding supplier cannot just give an off-the-cuff quote. Each customer’s order, is designed and tailored to the shape of the building, the access requirements and the environment.

A competent scaffolding supplier, hire or sales company will conduct a site visit to get a first-hand overview and establish various deciding factors, making sure the customer is equipped with the correct type of access for the building and the project they are contracted to.

Vital factors a scaffolding supplier, hire or sales company must establish prior to any dispatch are as follows;

- What are the ground conditions like? Are they level, uneven or perhaps sloping in areas

- What is the height and shape of the building?

- Who and what are in proximity to the scaffolding structure? Live overhead electrical cables and pylons, public, children, animals or dangerous industries?

- How many lifts are required? – set within the UK at 2m intervals

- What type of access is required for those working on the scaffolding? external access in the form of a scaffolding staircase fitted on external of the structure, or internal access provided by ladders and ladder access gates giving access from one lift to another – internally.

- Does the customer need a loading bay? Used to manoeuvre heavy materials such as bricks from ground level to the required platform

Once the scaffolding supplier has the above information, alongside a site drawing with planned view and elevations. The data and information is then processed through the scaffolding suppliers design software, such as CAD Smart Scaffolder.

Smart Scaffolder – 3D Design Software

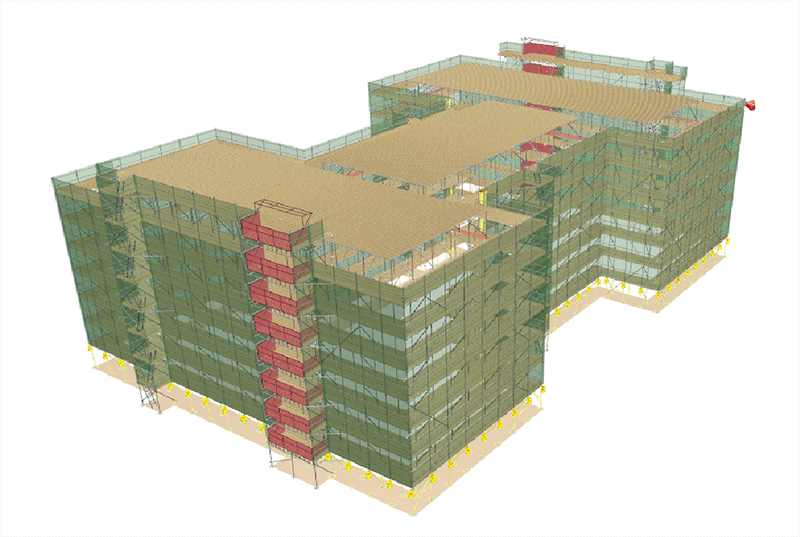

Once digitally processed, the dimensions of the building, the lifts required any additional complexities are catered for in a 3D digital mock-up which is then sent to the client or contractor for approval along with final costings for the hire or sale of the scaffolding to commence.

The customers scaffolding is then loaded in stillage pallets and delivered to the site it is required, installation services with some scaffolding suppliers are available. PHS Hire and Sales has the in-house benefit of having scaffolding contractors available to offer an installation and dismantling service. Some construction contractors have been trained in scaffolding installation and have their own resources to erect.

Either way, we strongly advocate it is not advisable to erect scaffolding yourself, unless fully trained and qualified in doing so.

Choosing a Scaffolding Supplier – with Expertise

Scaffolding to most is just a mass of metal used when things need built, repaired or renovated. It’s not until one is in need of scaffolding, the complexities of the services you additionally need come to light. Unless that is, you’re in the construction industry already.

When looking to hire or buy scaffolding, you can make your investment a lot more sound and supported by choosing a scaffolding supplier with manufacturing expertise. PHS Hire and Sales have the unique advantage of being part of the Pilling Group, working hand-in-hand with St Helens Plant to manufacture, repair and recondition all types of scaffolding, access equipment and supplies.

The benefit in hiring or buying from a supplier that has manufactured your scaffolding is, you have instant access to advice, guidance or support, should it be needed. You are also safe in the knowledge you know the exact age of your equipment, how many times it has been repaired and reconditioned and what safety standards it conforms to.

It’s rare, however – you can find an all-encompassing scaffolding supplier that has the ability to manufacture, design, supply and install. That said, it is possible and there are very reputable companies out there that can provide all scaffolding services required – or their network of associates can, in addition to the initial requirement of; scaffolding supplies, scaffolding hire and sales.

Summary

There’s many options available on the internet, search engines are full of listings with online shops claiming to be scaffolding suppliers. Many, will find upon contacting some of these suppliers that they are in fact just drop shippers. In a sense, middle men with a website, sourcing scaffolding from a supplier themselves.

Be cautious when seeking a scaffolding supplier and ensure that supplier, is in fact the supplier. Make a point of insisting on a site visit, should they decline, look elsewhere.

If you’d like more details on the wide range of scaffolding hire and sales available from PHS Hire and Sales, or to arrange a quotation or site visit, contact us on – 01698 535 699or email us at – info@phs.ltd